Nozzle spray principle

A nozzle is a device that accelerates a fluid and increases its kinetic energy. It usually consists of a narrow passage and an expansion section. In narrow channels, the fluid is confined, so the speed increases; In the expansion phase, the fluid is expanded again, so the speed increases further. Nozzles can be used in many different applications, such as rocket engines, jet engines, water pipes, flamethrowers, etc.

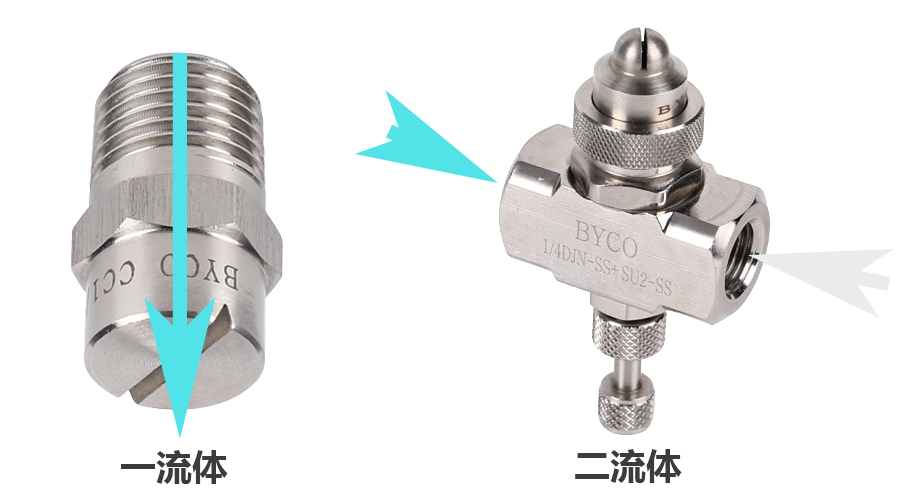

Nozzles are divided into one fluid nozzle and two fluid nozzles

Schematic diagram of one fluid nozzle and two fluid nozzle

One - and two-fluid nozzles, also known as single - and two-fluid nozzles, are common nozzle types. A fluid nozzle usually consists of a channel through which the liquid passes to form a single jet. This nozzle is commonly used for spraying water mist, coating, cleaning and other applications. It is a liquid pressurized nozzle, only suitable for the pump group to pressurize the liquid to the required pressure, and then spray through the nozzle. Compared with the two-fluid nozzle, the liquid particle size produced by the one-fluid nozzle is coarser and cannot be adjusted.

The two-fluid nozzle consists of two channels, a gas channel and a liquid channel. As gas and liquid pass through the two channels, they mix inside the nozzle to form a smaller, uniform jet. Such nozzles are commonly used for spraying liquid medicine, coatings, fuels and other applications. Inside the two-fluid nozzle, the gas is fully mixed with the liquid, which can better control the size and uniformity of the spray. However, if a liquid containing chemicals is used for two-fluid spraying, it may oxidize with the air and accelerate the decay rate of the liquid, so it is necessary to judge and pay attention to the amount of liquid used according to experience.

The main difference between a one-fluid nozzle and a two-fluid nozzle is the internal structure. A fluid nozzle has only one flow path, while a two-fluid nozzle has two flow paths, one for gas and one for liquid. This difference affects the function and application of both. Because the two-fluid nozzle needs to consider the problem of air tightness and liquid sealing, the multi-part design is usually used, which also makes the cost of the two-fluid nozzle higher.